- Heat Treatment and Water Quenching Process

Black plates and black coils produced by POSCO are transported to Dagang Stainless, where they undergo annealing in furnaces at 1050°C–1150°C, followed by automated rapid water quenching. This process achieves solution treatment, stabilizing the metallurgical structure to ensure superior corrosion resistance, mechanical strength, and uniformity in the final stainless steel products.

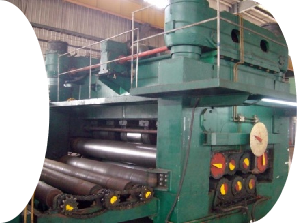

2.Leveling

Following solution heat treatment and water quenching, plates undergo precision leveling tailored to their thickness:

- Plates >40mm: Processed using hydraulic leveling machines for high-pressure accuracy and structural integrity.

- Plates 4mm–40mm: Treated with multi-roller leveling systems to achieve uniform flatness and surface consistency.

This thickness-specific approach ensures optimal dimensional stability and compliance with industrial specifications.

3.Cutting and Grinding

Leveled stainless steel plates undergo precision cutting along both lengthwise and widthwise dimensions using two computer-controlled underwater plasma cutting machines. Subsequently, sharp burrs are meticulously removed with grinding tools to ensure smooth, safe edges.

4.Shot Blasting and Acid Pickling Process After cutting, the stainless steel plates are vertically positioned and fed into a computer-controlled roller conveyor system. They undergo shot blasting and acid pickling to remove surface oxide scales and form a protective passive film, resulting in a pristine “white-finished” stainless steel surface.

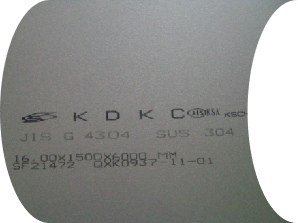

5.Quality Inspection and Marking

After acid pickling, the stainless steel plates undergo thorough quality inspection on a roller conveyor system. Following the inspection, automated inkjet marking is applied based on the material grade, dimensions, and compliance standards to ensure traceability and adherence to specifications.

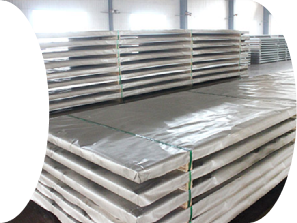

6.Weighing & Packaging After laser marking, each stainless steel plate undergoes precise weighing to ensure accurate specifications before being stored in the warehouse. The final packaging process utilizes moisture-resistant and anti-scuff materials, with secure bundling to prevent damage during transit. Strict quality checks are implemented at both stages to guarantee traceability and compliance with international shipping standards.